Fields of Application and Ways of Using Rubber Buffers

Rubber buffers from GUMMIVOGT are used in a string of applications and especially in mechanical engineering, electronics and the automobile industry. They are connected with objects in a variety of ways in these industries. The type of installation and the shape, colour and hardness of the rubber buffers depends on the desired duration of the attachment, the respective task of the rubber plugs and the expected loads and environmental influences. Round rubber buffers can be precisely fitted into existing openings or bores and hold firmly and reliably. At the same time, rubber buffers can easily be removed from the opening or replaced if necessary. Due to the possibility to use different round or conical rubber buffers, GUMMIVOGT products are extremely versatile.

Their central task is to absorb the kinetic energy of objects as vibration dampers to achieve a damping effect and thus effectively protect objects from vibrations. Typical ways of using rubber buffers are as buffer stops or as buffers for damping oscillations in, for instance, doors, gates and flaps. You will also find GUMMIVOGT rubber buffers used everywhere as the damping element where components are subject to vibrations or movements.

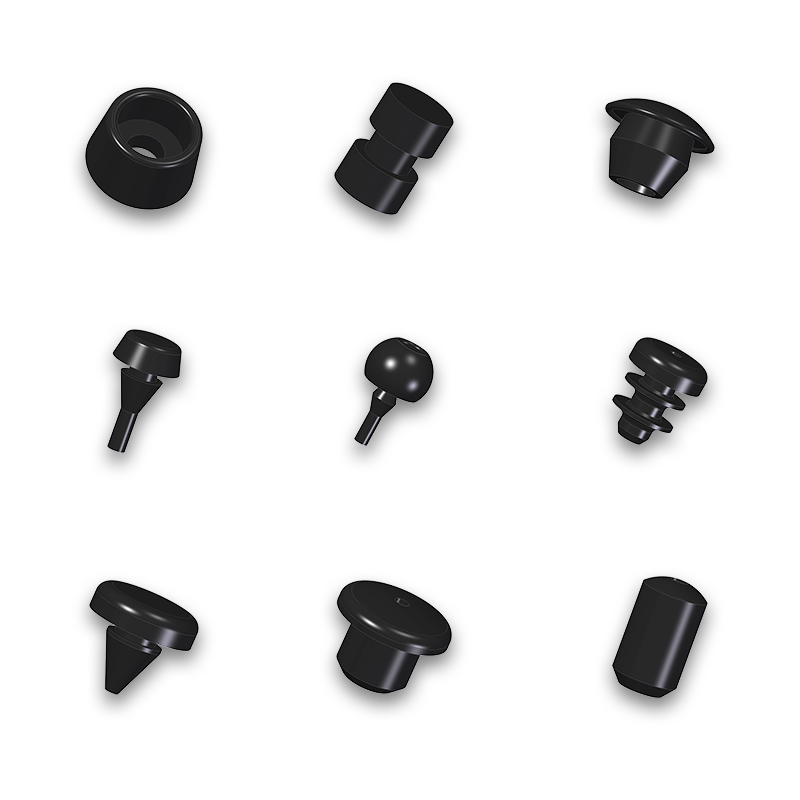

The properties of the rubber used reliably absorb the kinetic energies arising and thus stop their transfer onto other sections as vibration dampers. Another effect from using rubber buffers is closing of round ports and screw fittings in a precise and optically pleasing manner. The diversity of applications for rubber buffers is, of course, accompanied by a wide range of different designs of the products. Round rubber buffers are used as well as conical rubber buffers or special designs. GUMMIVOGT is your contact for all questions surrounding the design, application field and quality features of plugs, bushings, buffers and grommets.

Rubber buffers – Quality and service life

Various applications of the rubber buffers mean that they are subjected to widely differing load/stresses and atmospheric influences. Therefore, it is vital to turn to high-grade quality when selecting the rubber buffers. To maintain for as long as possible the service life and thus the protective and absorption effect of the rubber buffers, an analysis of the anticipated effects on them is indispensable. These effects include UV radiation, liquids, gases, both varying and extreme temperatures as well as the most diverse of mechanical loads which the rubber buffers may be subjected to. The greater the precision in anticipating the loads to come, the easier it is for the rubber buffer material properties to be adapted to them. In this way, the service life and protective effect of the rubber buffers can be retained for as long as possible.

The following hold good when using rubber buffers:

Basic material quality and processing impact decisively on the service life and reliability of the products. Whilst inferior product qualities are often invisible to the naked eye, they soon reveal their weaknesses in operations with possible fatal consequences, as a result. In manufacturing its rubber buffers, GUMMIVOGT thus sets its sights very much on unswerving quality and a Made in Germany in-house production. Rubber buffers from GUMMIVOGT are made throughout of a maximum EPDM quality. The material is UV and ozone-resistant and useable at temperatures between -40° C and +130 °C. Rubber buffers of the most varied of designs and hardness settings are available even in the standard delivery programme. Custom-order designs in economical batch sizes are also possible.